Optimal Timing for Concrete Countertop Epoxies

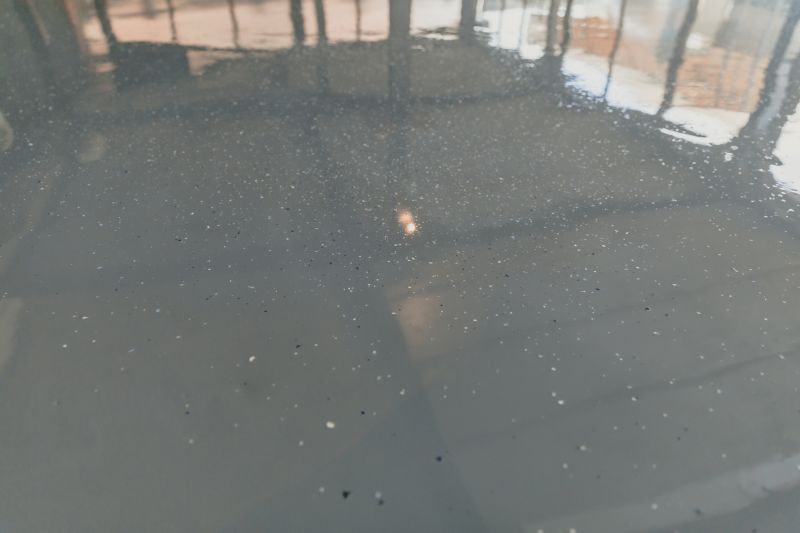

Applying concrete countertop epoxies at the optimal time ensures maximum adhesion, durability, and aesthetic quality. The ideal timing depends on environmental conditions, surface preparation, and curing stages of the concrete. Proper scheduling can prevent issues such as peeling, cracking, or discoloration, leading to a long-lasting finish.

Epoxies should be applied when ambient temperatures are between 60°F and 80°F to ensure proper curing and adhesion.

The concrete surface must be fully cured, typically 28 days, before applying epoxy to achieve optimal results.

Low humidity conditions, ideally below 70%, help prevent moisture from affecting epoxy adhesion.

Avoid application during rain or high humidity days to prevent moisture entrapment and curing issues.

Ways to make Concrete Countertop Epoxies work in tight or awkward layouts.

Popular materials for Concrete Countertop Epoxies and why they hold up over time.

Simple add-ons that improve Concrete Countertop Epoxies without blowing the budget.

High-end options that actually feel worth it for Concrete Countertop Epoxies.

Finishes and colors that play nicely with Concrete Countertop Epoxies.

Little measurements that prevent headaches on Concrete Countertop Epoxies day.

| Timing Factor | Details |

|---|---|

| Temperature | Apply when temperatures are between 60°F and 80°F. |

| Surface Cure Time | Wait at least 28 days after pouring before applying epoxy. |

| Humidity | Ensure humidity levels are below 70% for optimal adhesion. |

| Weather Conditions | Avoid applying during rain or high humidity days. |

| Surface Preparation | Complete cleaning and etching immediately before application. |

| Time of Day | Mid-morning to early afternoon is preferable for consistent conditions. |

Concrete countertop epoxies are specialized coatings designed to provide a durable, glossy finish that enhances the appearance of concrete surfaces. They are formulated to resist stains, scratches, and moisture, making them ideal for kitchen and bathroom countertops. The application process involves careful surface preparation, including cleaning and etching, followed by precise mixing and application of the epoxy. Proper curing time is essential to achieve maximum hardness and adhesion, which can significantly extend the lifespan of the surface.

Statistics indicate that correctly timed epoxy applications can improve surface resistance by up to 50% and extend the durability of concrete countertops by several years. Epoxies also offer a wide range of color and finish options, allowing for customization and aesthetic enhancement. The curing process typically involves a chemical reaction that is sensitive to environmental conditions, underscoring the importance of applying epoxy under suitable temperature and humidity conditions.

A 60-second routine that keeps Concrete Countertop Epoxies looking new.

A frequent mistake in Concrete Countertop Epoxies and how to dodge it.

Small tweaks to make Concrete Countertop Epoxies safer and easier to use.

Lower-waste or water-saving choices for Concrete Countertop Epoxies.

The short, realistic tool list for quality Concrete Countertop Epoxies.

Rough timing from prep to clean-up for Concrete Countertop Epoxies.

Interested in enhancing concrete surfaces with epoxy coatings? Filling out the contact form can provide more information on suitable timing and application techniques to achieve optimal results.